I’m running the bed that came with my Ender 3 pro (using a pei sheet, this is repeatable with glass too), been having this issue for a while I think. Is it time to replace the bed?

Update: Figured it out, what my bl touch was attached to was very loose, and was going up on the far side of the x gantry. and it’s now fine.

Took me a moment to realize this wasn’t a figure of your bed that you sleep in

This is a mechanical issue with your motion system, not your bed. If it were the bed the probably would not be consistent between different bed surfaces.

I would make sure the roller paths are clear and flat the entire length of the path. More than likely that is the cause. Also check that the cables are sufficiently long so they aren’t putting excess tension on the tool head or bed at the extents of travel.

I had a roller lifting up at the edge of the bed that caused this. In my case is defined the bed mesh to large in klipper and the hot end was pushing up metal slope on thex gantry.

Make sure there isn’t too much tension on the cables to the hotend assembly. Could be pulling too tight and lifting a bit when it gets too the far side

This is the right answer. You’re hot end is pulling tight and causing this skew.

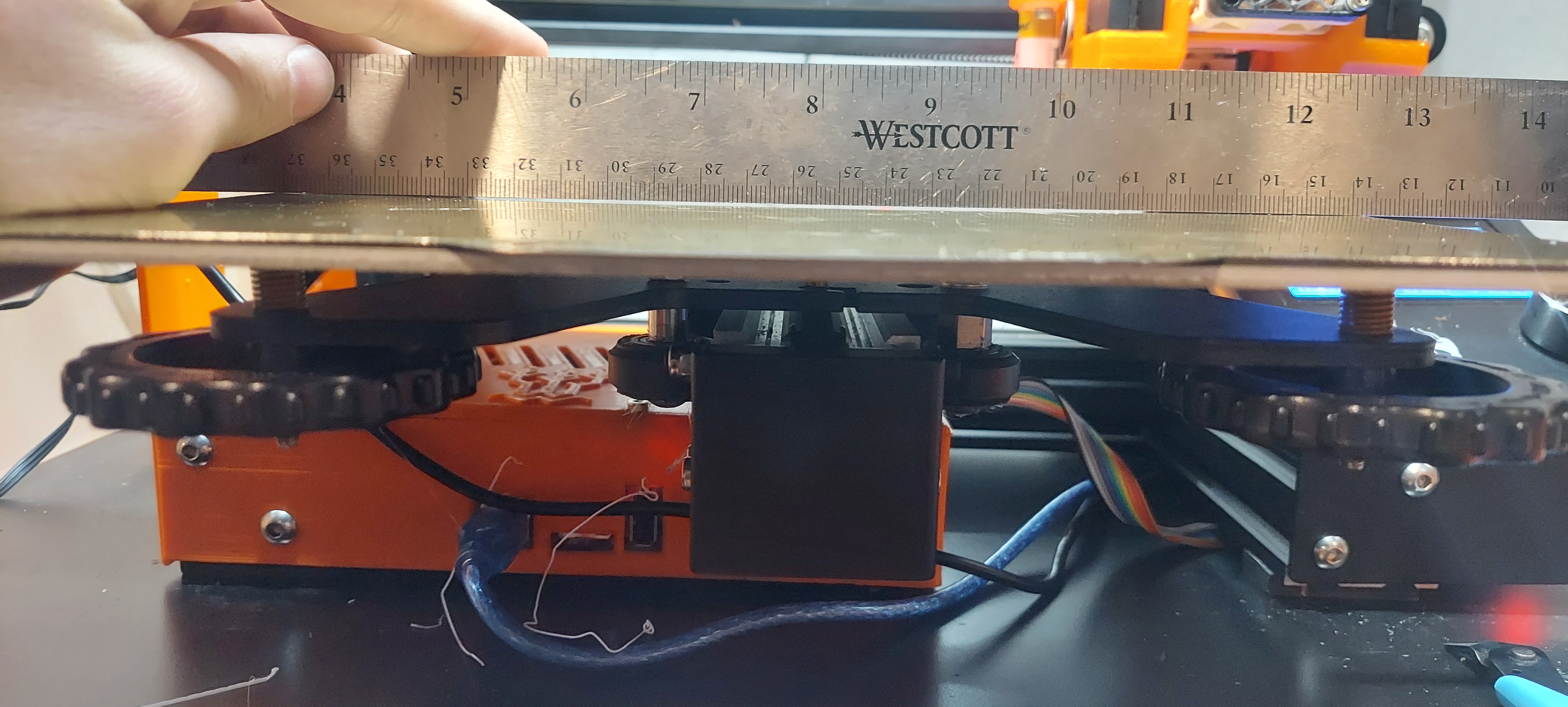

Put something flat on your bed. It should have a noticeable gap between the bed and the piece

Or you have something wrong with the level sensor

I agree it seems really odd how consistent the warpage is along the back edge. Is there a sticker or something on the bed there that the level sensor is hitting?

There’s not these are pretty broken in sheets that I’ve had for a while

You said it’s the same without the sheet, just directly on the glass? If so, I’d definitely consider swapping it, though check it first with a straight edge like the other person suggested. Just stick a flashlight behind it and look for light to come through. Really odd warpage though.

My Artillery Sidewinder glass bed was also warped but it looked like a bowl shape not like a Fast and Furious car with a giant spoiler.

I just put a metal ruler across it, and there’s a noticeable gap

This to me looks like it’s time to buy a new bed, stick with Creality or is there a better brand to upgrade to?

I’d get a good tempered glass sheet, creality sells good ones cheap. it’ll go right on top of this. You might use a bit of thermal paste to seal those gaps and make sure it heats evenly. One side of the glass will be textured, I prefer the smooth side.

Last time I checked (which admittedly was over a year ago) people were saying that Creality sourced their PEI sheets from a reputable company (which name has also slipped from my mind) so they should be good quality. On the other hand, I believe Creality used to put genuine Meanwell PSUs in their printers a long time ago, and they changed to cheap unbranded ones to save money later.

Some thoughts though… The print surface is thin and flexible, so if it dips like that I think it’s more likely the carriage under the bed that is bent. I.e. replacing the print surface might not fix it. A glass bed might be able to even it out, assuming you don’t clamp it down too hard, since glass is also a little bit flexible. If you want smooth glass, it’s usually cheaper to get a mirror cut to size than buying a printer bed. The reason for using a mirror instead of regular glass is that mirrors have to be very flat in order to not distort the image, while window panes can be a little uneven without anyone noticing.

Personally I’m not a huge fan of glass, but here are some pros and cons so you can decide for yourself:

Pros - Can compensate for a bent bed carriage. Cheap (especially if you get a mirror). Quite durable, lasts a long time. Withstands chemicals, for example if you need to remove ABS residue using acetone. Cons - Heavy, which will limit the maximum acceleration you can use before getting print artifacts. Not the best adheision so you might need to use glue or something to improve it. Unlike PEI/steel beds you can’t bend the sheet to pop the model off, so you have to wait for it to fully cool down before you can remove the print (can take around 30 minutes)

But with all that said, you have a probe so it ought to be able to compensate for that dip in the bed easily. Maybe increase the number of measure points if it’s causing problems?

I got a glass bed then and simply put’ it on the stock bed. Takes 5 degrees more heat and a little longer to heat up but I am very happy with it. Btw, when you are at it: I would isolate the bottom side of the bed to conserve energy. You can buy ready made isolations with a glue- and an aluminium side.

IDK, that’s weirdly consistent